Coils born under a good "star"

Marina Porta

The offer that the polyamide market offers to the electrical and electronics sector is wide and differentiated: a range of possibilities which, in a moment of stagnation like the current one, could help companies achieve the objectives of better quality of the finished product and a greater increase in productivity. This is precisely the path pursued by a company in the sector, which has decided to revolutionize its production by using a latest generation polyamide.

Created to meet the demands of the textile industry, polyamides, thanks to their mechanical, thermal and chemical resistance, have found fields of application in the sector of technical articles and industrial components. If the self-lubricating characteristics soon proved to be crucial for the production of gearbox and motor parts, and the high wear resistance was ideal for ski boots and shoe soles, the good electrical properties and flame resistance made irreplaceable polyamides for the electrical and electronics industry. In this field, in fact, the products are subjected to intense stress from both a thermal and electrical point of view: «The supports for the electrical windings of current transformers must be able to withstand high temperatures for a long period of time» stated Gianluca Ronchetti, partner of Cartoplast (Monza, Milan). But this is only one of the requirements that these components must satisfy, in reality, in addition to high thermal and dimensional stability, they must also be characterized by excellent self-extinguishing. In recent years a lot has been done to improve the performance of these pieces, but much more can be done: Ronchetti is also convinced of this, who told us how he optimized the properties of his products, using Rhodia's Technyl Star as an alternative to traditional polyamides.

Polyamides in the electricity market

The panorama in which Cartoplast operates is that of insulating supports for electrical windings and accessories for current transformers: a vast market, not so much for the number of companies operating in it, but for the diversification of the shapes and dimensions of the components made . Cartoplast itself has a total of almost 2,000 mold parts which, in addition to producing around 12 million pieces every year, allow it to print special components. When we asked Ronchetti what his objectives are for the future, he confided to us an idea that is becoming a priority: «I would like to reach the highest quality levels typical of the big players in the sector». An ambitious project, but given his age, why shouldn't this young entrepreneur dare? For the moment his strategy is based on enhancing quality and, as head of raw materials, he has recently decided to bring a burst of innovation to the company's production by introducing a completely new material which, as he himself admits, he discovered between the lines of the specialized press. «In this period of recession - declares Ronchetti - it is necessary to react by investing in innovation. This was the fundamental reason that pushed us to rationalize our efforts in the production of new molds and in the search for alternative materials. In particular, we wanted a polymer capable of offering superior performance and above all not yet "explored" by the competition, this to increase the competitiveness of our products.The choice fell on Technyl Star by Rhodia, a newly developed polyamide, which allowed us to stand out at the Cwieme fair in Berlin, held last June." A success still at an embryonic stage, of which Cartoplast seems to be starting to reap the first fruits.

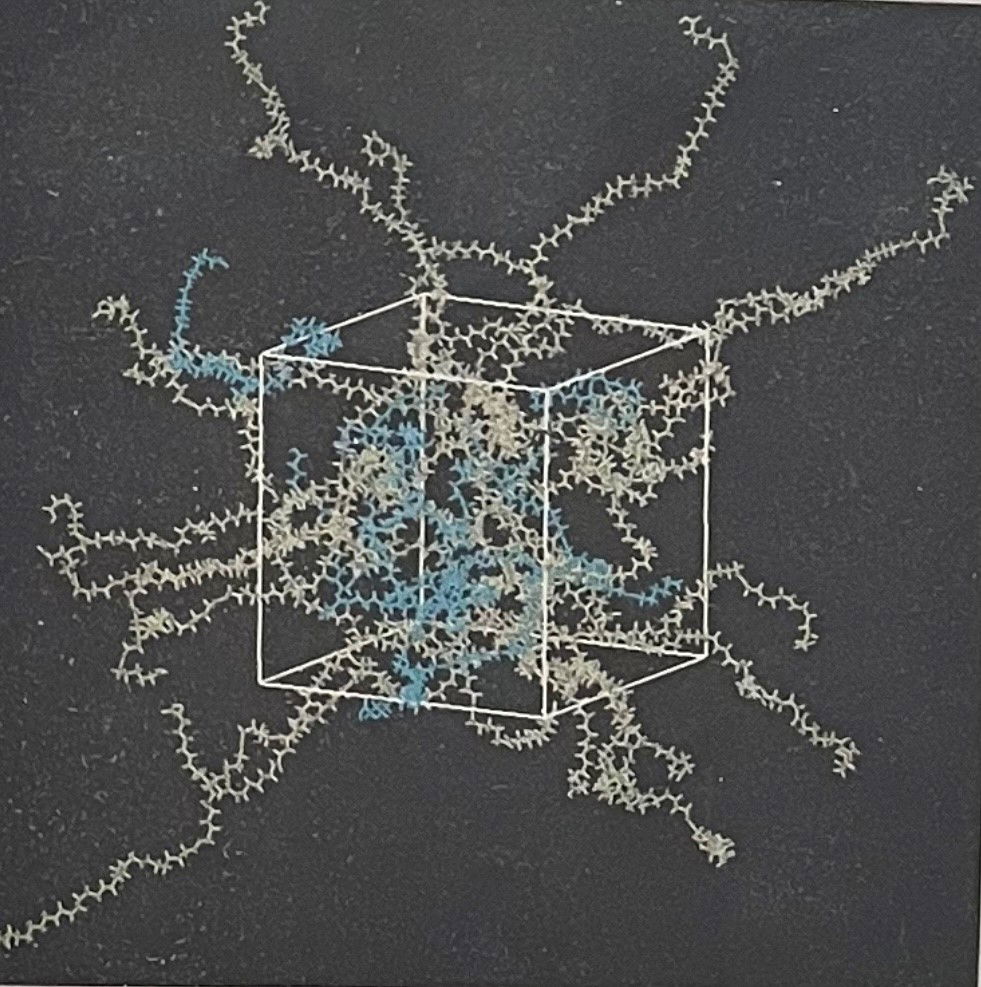

A polyamide with a star structure

In a now mature sector, where innovations are increasingly heading in the direction of on-board machine additives, Technyl Star stands out for its decidedly singular structure and for those properties that derive directly from the molecular weight. It is now well known that polymers are made up of more or less branched linear chains, and that as the molecular weight increases the mechanical characteristics improve, while the fluidity worsens. The new molecule, however, has a totally different structure, a star. In practice, it consists of a central core from which several arms originate, the total length of which is comparable to that of a linear polyamide; obviously this makes the molecular weight not dissimilar to the chain compound, but what varies is the hydrodynamic volume, which is smaller. What advantages does this conformation bring? «A significant increase in viscosity, around 100% with the same molecular weight, says Adriano Bellini, sales manager for the electrical and electronic sector of Rhodia and a high capacity to absorb fillers and reinforcements (up to 60-65%) with excellent results in terms of resistance and surface properties." What benefits the material allows at an application level is a question we ask Ronchetti, who, listing the best qualities of the finished piece, highlights how it has greater rigidity, superior mechanical characteristics, as well as the ability to maintain dimensional stability very high, often not achievable with traditional polyamides. Ronchetti continues: «We all know that polyamides are highly hygroscopic (especially PA 6 and PA 66), a property often considered an advantage because it increases elasticity, but which in our case is undoubtedly a defect, since it compromises dimensional stability. The use of Technyl Star allowed us to minimize this inconvenience." In addition to the technical characteristics, Bellini invites us not to neglect the surface appearance: homogeneous, smooth, shiny and paintable.Beyond the performance of the finished piece, perhaps the most considerable advantage deriving from the use of Rhodia polymer is the increase in productivity, which can be achieved above all in the molding of coils for large transformers, a product that Cartoplast considers the "strong piece " of the company's production «From an initial evaluation - states Ronchetti - in six-seven months of full production we have achieved an energy saving of 50%, acting above all on the injection pressure, which represents the real energy consumption of the process. The high fluidity of Technyl Star allows it to operate at considerably lower pressures than those applied in the molding of traditional polyamides. At the moment we have managed to reduce the injection pressure by 45-48%, and this modification has allowed us to shorten the production cycle considerably. Unfortunately, this variation does not have a significant impact on the number of pieces produced in the unit of time, because one of our critical variables is the cooling duration, a parameter that we prefer not to shorten so as not to risk compromising the dimensional stability of the finished product . Let's also not forget that greater fluidity improves the "fil-ling" of the mold, a detail that allows us to operate with molds with multiple cavities".

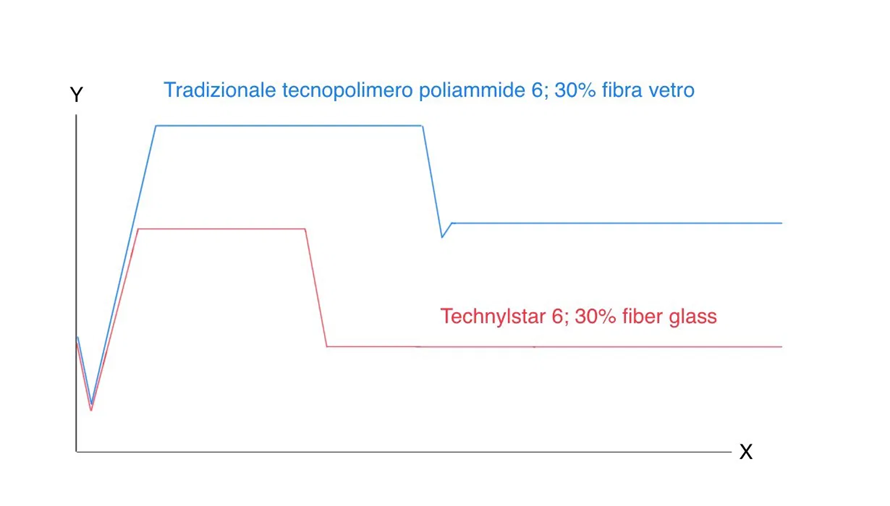

Fluidity even at high charge

The high fluidity is not significantly compromised when the material is loaded with high quantities of reinforcement: a potential that has allowed Rhodia to develop grades with mechanical and thermal characteristics comparable to those of "superpolymers". To confirm this, Ronchetti claims to have obtained even better molding performances by operating with fillers of 50%, compared to the 30% normally used to create the products he produces. To justify this experimental evidence, Bellini specifies: «The polymer shows an almost Newtonian rheological behavior (i.e. like non-polymeric fluids, for example water, ed.), a property that leads to simpler compounding and molding, especially in presence of glass fiber contents and high mineral fillers. Experimental tests carried out with Technyl Star and with linear polyamides 6 with different filler content have demonstrated that, in terms of spiral tests, almost doubled lengths are obtained for Technyl Star polymers.This is a peculiarity that entails great freedom in the design and molding of pieces that require high melt flow." To conclude, Ronchetti explains his considerations regarding shrinkage, a well-known drawback linked to the use of polyamides: in fact, the contraction of the volume of the product during the manufacturing phase is approximately 3%, while during the solidification phase it varies from 4 to 7%. «We have not yet systematically addressed the problem of withdrawal, so far we have used the data reported on the technical sheets. However, even if we have not had any problems, we wish to carry out targeted tests in the short term: before moving on to using Technyl Star on all production lines, I believe it is appropriate to also verify this parameter".

Predictions of a bright future

The potential of Technyl Star seems to have satisfied Ronchetti, especially given the positive appreciation of Cartoplast's customers, who declared that they had managed to slightly reduce their production times. After listening to Ronchetti's arguments, we were not surprised by Bellini's statement: «Rhodia has focused heavily on this latest generation polyamide, a choice deriving from the awareness that to survive in an increasingly global market it is necessary to invest in innovation. Another cornerstone around which the philosophy of the company for which I work revolves is the "integrated supply chain", a belief that has led to the development of an industrial reality that ranges from the production of raw materials (caprolactam for nylon 6; nitric acid and hexamethylenediamine for nylon 66) until polymerization. Currently, for the technopolymers sector, we are second in the world after Du Pont, but we hope that our corporate strategy can, by 2007, take us to world leadership."

Marina Porta

November 2002