A new material arrives in the company: AKULON ULTRAFLOW

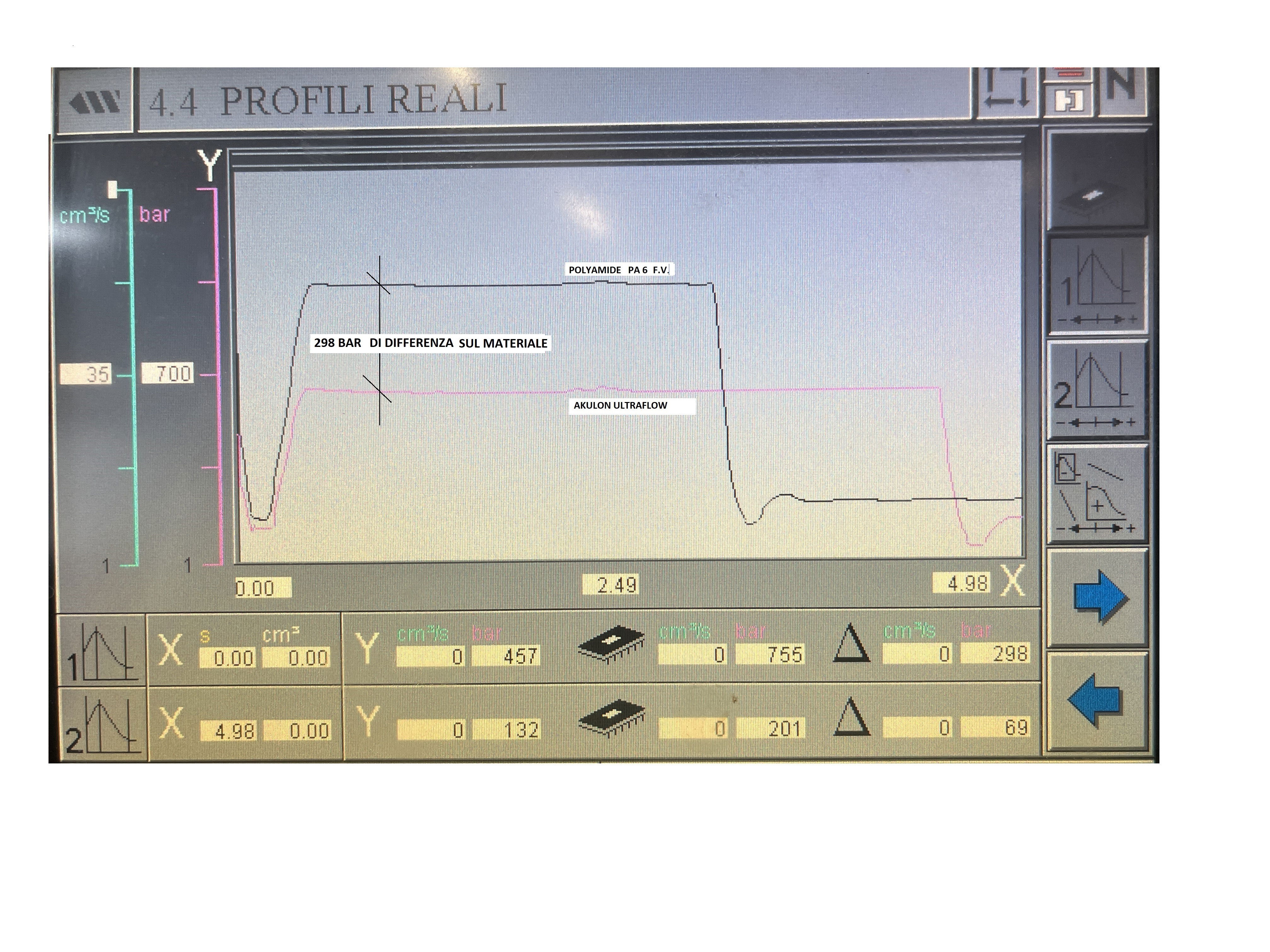

The company Cartoplast S.r.l. of Monza is experimenting with a type of high-performance plastic material: AKULON ULTRAFLOW. The use of the material is dedicated to particular products that require certain molding conditions such as reduced filling pressures and faster plasticization, due to the particular formulation of the polymer with high flow fluidity especially for multi-cavity molds, allowing faster processing cycles . Cartoplast uses Akulon Ultraflow on an experimental basis on components with variable thicknesses and vertical flow impact surfaces. The Akulon Ultraflow used is a PA6 technopolymer reinforced with glass fibre, heat stabilised. It has a low viscosity index allowing the filling of all mold cavities with less effort and wear compared to traditional polyamides. The graph below, in the presentation of polyamide, specifies that the use of Akulon Ultraflow can reduce injection pressures by approx 40 - 50% compared to the standard.

Graph extrapolated from the molding systems carried out by Cartoplast.

Graphic elaborated by the molding systems carried out by Cartoplast

The Envalior production material is today mainly used for engine covers, intake manifolds, exterior mirror caps for cars, electricity and electronics, furniture and power tools.